Four Keys to Managing Peak Produce Season Capacity

Whether your business dabbles in fresh produce or not, peak harvest times are a crucial element of every shipper’s supply chain operations. Trucking capacity quickly deteriorates in certain markets throughout the year as carriers haul regional outbound produce nationwide, causing those businesses that fail to plan ahead to pay exorbitant rates for otherwise routine shipments.

From understanding geographical and seasonal trends to preparing storage ahead of time, here are First Call’s four keys to successfully navigating peak produce season’s capacity challenges.

1. Pay Attention to Key Regional Harvest Times

Today’s consumer wants what they want regardless of whether it’s “in season,” forcing produce shippers to get creative when it comes to keeping shelves stocked year-round. Produce growers and sellers hope to keep up with these somewhat exaggerated consumer expectations by sourcing produce from a variety of regions and climates — it’s always summer somewhere, right?

Spring (March to May): Warmer temperatures ripen tree fruits like cherries, bananas and mangoes in the U.S. each spring, while Chile, Peru, Costa Rica, Mexico and Honduras supplement the demand for such fruits year-round. Lettuce, asparagus and fresh herbs are also ready to harvest around this time.

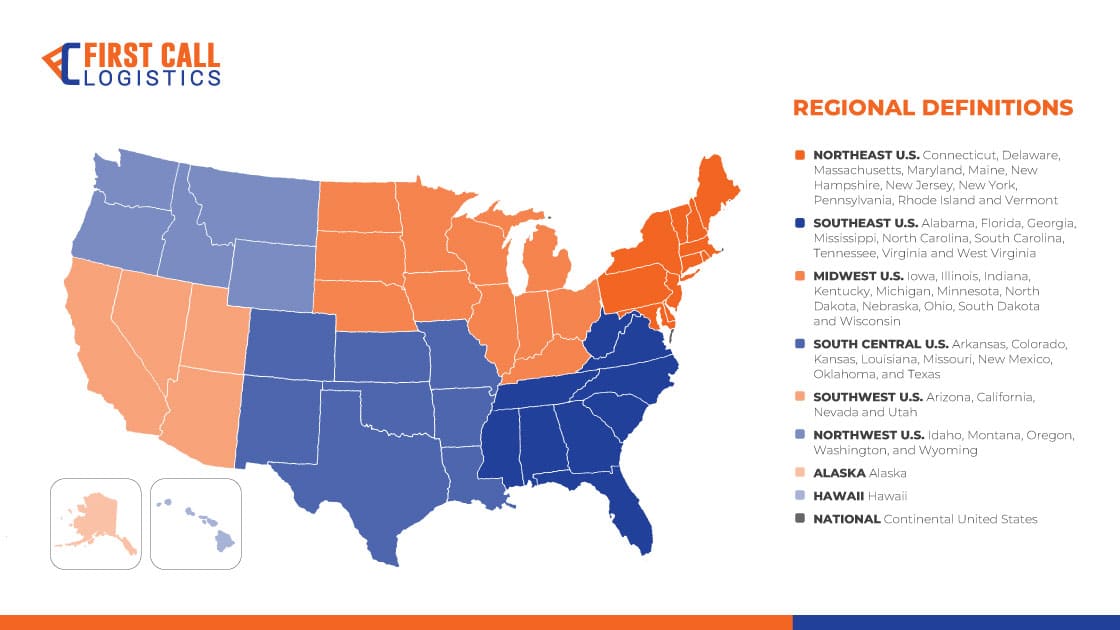

The Pacific Northwest, California, Florida and the Southeast are considered major domestic spring produce hubs.

Summer (June to August): While the global produce scene has largely reduced the strict seasonality of most major crops, the sunny stretch from Memorial Day to Labor Day remains the busiest time of year for domestic produce shipping. Berries, melons, carrots, bell peppers, tomatoes and peas are staples of the summer harvest season, reliably crowding Californian, Midwestern and Pacific Northwestern shipping lanes to max capacity.

Pay special attention to July 4th weekend, when watermelon sales quickly deplete available capacity as certain other major holiday-centric products tend to do.

Fall (September to November): Peak season for apples, pumpkins, squash, radishes and other root vegetables typically rings in the fall with some capacity strain in the Northeast, Midwest and Northwest during these autumn months.

Winter (December to February): Citrus, onions and root vegetables are harvested at this time. Florida, Texas and California have some of the mildest winters in the country, and are thus hotspots for winter produce.

Most industry professionals find it prudent to line up shipping alternatives a few weeks before and after each region’s estimated busy season, as a crop’s precise harvest dates shift from year to year.

2. Anticipate Strained Capacity Near Major Produce Hubs

Roughly two million farms are currently in operation throughout the United States, aiming to meet the endless demand for fresh-from-the-farm items (regardless of climate or geography). These are the locations from which most of the country’s perishable food supply is derived, and the hubs shippers need to plan around to avoid last-minute rate hikes or entirely unavailable capacity:

Yuma Valley, AZ: Prized for its fertile soil and averaging 350 days of sunshine a year, the Yuma Valley produces an estimated 90% of all the leafy greens consumed in the U.S. annually.

Trucks carry fresh greens out of Yuma roughly six months out of the year, with each of the valley’s nine salad plants capable of producing more than two million pounds of lettuce per day (loaded on 1,000+ trucks per week) at peak harvest time.

San Joaquin Valley, CA: Over 3,000 square miles of the San Joaquin Valley’s mineral-rich soil is dedicated to agriculture. Dry, moderate summers and cool, temperate winters mark the valley as one of the most productive agricultural regions in the country, with tomatoes, berries, grapes, citrus, almonds and more than 250 other crops growing within its borders.

Though it’s estimated the valley produces a quarter of the U.S. food supply, San Joaquin remains susceptible to many of the issues plaguing other agricultural hubs; labor shortages, water scarcity and local air pollution all pose potential threats to the valley’s productivity.

Salinas Valley, CA: There are many produce-rich areas to be found within California’s state lines, but only the coastal Salinas Valley earns the unique distinction “Salad Bowl of the World.” Salinas is the country’s primary producer of lettuce and salad greens, alongside other key crops like peppers, broccoli and cauliflower.

Despite area farmers battling both area flooding and the spread of “impatiens necrotic spot virus” (a harmful plant disease), Monterey County reported an increase in crop production value by more than $500 million in 2022.

Rio Grande Valley, TX: One of the most diverse agricultural regions the country has to offer, the lower RGV is a key producer of grapefruits, oranges, onions and watermelons. The RGV is also under a particularly strained set of circumstances as of late — irrigation issues stemming from a low Rio Grande River (so low that insurance companies refuse to insure crops) have seen much of the area’s protected agriculture production move to Mexico to save on labor.

The valley’s location along Texas’ southernmost border also serves as a natural artery connecting the U.S. and Mexico’s cross-border shipments. Thus, carrier capacity is often pushed to its limit during the busy summer season, with the Department of Agriculture estimating about half of the nation’s imported vegetables (and 40% of its imported fruit) presently originate in Mexico.

Willamette Valley, OR: The Willamette (will-LAM-it) Valley supplies the country with a wide range of crops, but the real draw here is its fresh strawberries, blueberries, and blackberries. The valley also boasts ideal conditions for growing wine grapes, with its vineyards and wine production seeing a recent explosion in popularity.

Columbia Basin, WA: Mixing fertile soils and a semi-arid climate, the Columbia Basin is a vital contributor to the nation’s fruit production industry. It is most famous for its apple and cherry orchards, as well as pears and peaches.

East Coast: The Eastern Shore makes this list as the first hub known for its seafood and poultry production, with a focus on crab, oyster, and clam harvesting from the Chesapeake Bay. But the East Coast in general provides a wide variety of year-round produce, as the region’s agriculture chases the sun south from New York to Tennessee, North Carolina, Georgia and ultimately Florida for the winter, only to reverse its course once warmer conditions return in the spring.

South Florida: The southernmost region of Florida is renowned for its citrus fruit production. Oranges and grapefruits in particular tend to thrive in the region’s sunny, subtropical climate.

3. Forecast Your Company’s Expected Capacity Needs

Knowledge of a given region’s peak harvest times and seasonal challenges is at its most useful when paired with real-time data. Market data through tools like FreightWaves SONAR and DAT indicate which areas are currently experiencing (or may soon experience) strained trucking capacity. Aided by historical data and hands-on experience with region-specific produce challenges, a good 3PL provider helps partners navigate real-time trends and establish carrier contracts well ahead of time — ideally at more favorable rates.

Depending on the nature of goods and their specific shipping requirements (think temperature-controlled freight), 3PLs can also aid in diversifying a company’s carrier network to avoid any single disruption shutting down a produce shipper’s whole operation.

4. Have a Detailed Plan in Place

Businesses need to account for longer lead times when shaping their production and shipping schedules around a region’s peak harvest season. Lead times can be particularly tricky in produce, since precise harvest dates can be hard to nail down months in advance, but an open channel of communication with agricultural suppliers can mitigate this challenge considerably.

Checking in regularly with suppliers provides valuable insight into crop yields, expected harvest times and potential delays or disruptions creeping up on the horizon. Together with the real-time market insights mentioned above (either through publicly-available tools or through a 3PL provider), produce shippers should be armed with all the information required to ensure their capacity needs are met during even the most hectic of harvest seasons.

While some produce is packed and shipped in temperature-controlled reefers for immediate distribution among grocery stores’ fresh foods aisles, some shipments may require frozen storage space prior to delivery. Investing in reliable warehousing and storage facilities equipped to handle frozen food items allows companies to better manage the flow of produce and avoid overloading carriers during peak seasons.

First Call began as the logistics arm of a produce company — that means we take our fruits and veggies seriously. As your trusted logistics partner, we’re committed to consistently delivering your goods on time and in prime condition. Contact us today to speak with one of our produce shipping experts!

Simplify your Next Shipment with First Call Logistics

More Logistics Resources:

- Article: The Latest in Food Supply Chain Safety

- Article: 5 Logistical Challenges Facing the Food and Beverage Industry

- Article: An Introduction to Temperature-Controlled Shipping

- Article: Truckload Supply and Demand

- Press Release: First Call, Horton, Grow Farms Texas Team Up for Irving, TX Expansion

Get the latest supply chain news and updates directly to your inbox.